22 OCT 15: Page 33-4 steps 7-10, page 33-5 steps 1-2, page 38-2

step 6: 5 hours

Dimpled the holes in the F-1024 seat floors and

associated under structure. Dimpled the

holes in the baggage floors. Riveted the

brake pedal assemblies together:

Riveted the access plate doublers to the

floors. These access plates will make it

possible to get to the step bolts:Cover plate installed:

23 OCT 15: Page 33-5 steps 3-11, page 34-4 steps 3, 5: 3.75 hours

Dimpled the F-1022 baggage floors, understructure,

and stiffeners. Riveted stiffeners to

the F-1022A-L/R baggage floors:

Dimpled the baggage door parts. Unfortunately, I’ll have to do this part

over. I assume my dimpling in the frame

was insufficient. When I riveted the

frame to the door, most of the dimples cracked.

I ordered new frame pieces from Van’s.

Should be a relatively quick replacement.

27 OCT 15: Conduit / Sound proofing install in rear floors: 4 hours

Installed soundproofing under the rear floors in

prep for riveting the baggage and rear floors.

Made a couple tabs to hold the wiring conduit as it runs through the

baggage bulkhead lightening holes:

Soundproofing installed with the conduit run through

the rear seat floors:

28 OCT 15: Page 33-6 step 2, 33-7 1-4, 33-8 1-7, 33-9 1-3: 8 hours

Riveted the F-1024 seat floors and the F-1022A

baggage floors. Riveting the inboard

flange nutplates:

Baggage floors riveted in:

29 OCT 15: Page 33-9 steps 4-8, page 35-2 steps 1-2, page 35-3

step 3, 42-4 3-6: 5 hours

Match-drilled the F-1006E upper baggage bulkhead

corrugation. Final-drilled all the holes

in the F1016C-L/R floor pans. Due to the

extreme difficulty of inserting and removing the floors, and the fact that all

the floor ribs are already drilled and dimpled, I decided to just final-drill

the floor holes while uninstalled and only install the floors once when it is

time to rivet them in place.

Match-drilled the F-1034F seat back brace closeout to the F-1034B seat

back brace. Riveted the rear seat frames

together, cut and bent the seat hinge pins, and installed the seat backs. Really cool to see the fuselage taking shape!

30 OCT 15: Page 35-3 step 5-6, 35-4 1, 35-5 1-2, 5-6, 35-6 1-2,

35-7 3-4 35-10 1, Prekote, Prime: 5

hours

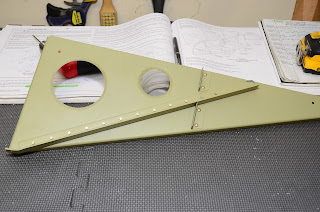

Final drilled all the remaining interior covers in

prep for priming. Last big batch of

priming for the entire airframe:

Had some primer left

over, so I decided to knock out one of my favorite tasks – and one that I have

put off for some time; priming the inside of the control tubing. An annoying, but necessary task:Amazing to think that this is the only metal in the entire airframe that I haven’t primed!